“The Low Price” of the textile discounter KiK – consequences for labour conditions in textile factories in Bangladesh

1) Introduction

This case study wants aims to highlight a special part of the worldwide globalisation movement. The It concentration focuses lies thereby on the textile industry of in low wage countries exemplified at by the case of Bangladesh. The Sstarting point for this study is the German garment discounter KiK and its pricinge politicspolicies. To bBuying cheap clothes in Germany is something really normal for us today, but most of us do not consider or take care about where these clothes come from, by whom they are produced at and under what circumstanceswhich circumstances, for example labour conditions. This case study should offers a first inside -view into the economic methods that lead to such cheap prices and the humanity aspects considered withthat accompany them it.

At the beginning of Chapter 2 I give a short presentation on thef Bangladeshi economy and the social situation. It is important to see labour conditions not only in comparison to Western standards, but also to local living conditions based on the real actual basic needs of economic survival. Globalisation as an influencingtial criteriafactor on labour conditions is mentioned in the next paragraph. It will be shown that globalisation has had an impact on the Bangladeshi textile industry which was has been both positive ands negative for the economy and the workers.

The Chapter 3 is dedicated to the German garment clothing discounter KIK and in general to the strategies huge discounters use to determine their primarye costs. The profile of the KiK company will be presented and its advertising promises will get be discussed. The market power of big discounter companies is the subject of the next paragraph. As an example, the different price components of a T-shirt are shown. Additional aspects of the interaction of garment clothing discounters and the textile industry at in low wage countries are the purchasing practises of the business companies. Three tendencies can be made updemonstrated that are ofhave a significant impact on the textile industry. Ans interesting last point in this chapter is the KiK company statement on their behaviour as bulk buyer will be shown. This implies the a code of conduct and how it is put into action and controlledmonitored.

After Following the previous chapter which did presented what a discounter does to achieve little low prices and my introduction concerning Bangladesh as a place that offers cheap work, I like to focus on the Bangladeshi labour standards in detail in this Chapter 4. A research study gives concreteprovides specific inside views on into the insufficient inadequate labour conditions in garment factories which produce cheap clothes for the Western market, also including for the KIK company in Germany.

The missing inadequate labour conditions lead me to the next and last final Chapter 5. It is dedicated to a final summary and a futuren outlook. In this chapter I want to discuss the usefulness of the code of conduct in general, and in particular to this example. During a the final outlook I like to present some possible strategies for the future, including, for example, more powerful conducts and under which political circumstances they can get active.

2) Bangladesh – economic and social facts

2.1 Geographic and social information

A population of about 164.,4 million people lives In Bangladesh[1] in an area of 147.570 square kilometres. That makes the country “one of the most crowded on Earth”[2]. Bangladesh lies on the Ganges-Brahmaputra river system which makes the land very fertile. The annual floods on the one hand help and are welcome because they give fertility to the land, but on the other hand they sometimes destroy the harvest and kill the people who are living near the river. Most Bangladeshi people make a living from agricultural production, for example “wheat, barley, maize, potatoes, pulses, bananas and mangoes”[3]. The Bangladeshi people are very poor. Around 25% of the population suffers from hunger. The textile industry contributes enormously to economic development. Two million people work in 3.500 factories. About 85% of them are women from rural regions who need to work in the cities because of a job shortage in their home regions. Work in the textile factories is their only chance to receive income that helps the survival of the family.[3]

2.2 The Bangladeshi garment and textile industry

The “Agreement on Textiles and Clothing” (ATC) of the World Trade Organisation in 1995 was designed to restrict the massive export of clothes produced in emerging and developing countries to industrial countries.[4] The ATC restricted the imports of textiles and clothing through quotas. Huge clothing producers and exporters like China, India or Hong Kong were affected by these quotas. Bangladesh was not affected because it was a very poor developing country and therefore took its chance and established a growing textile industry. Exports of clothing rose from 600 million USD in 1990 to about 8 billion USD in 2006.[3] The export products of Bangladesh shifted from raw materials, like jute and jute products (90%) to clothing based on cotton. “The textile and clothing industry now accounts for 76% of the total export volume of Bangladesh.”[3] Fishing (7%) and raw material jute (5%) are the two other important export-products of Bangladesh. The Bangladeshi economy today is very strongly orientated toward the textile industry. That may cause problems if exports decline and if the required raw material for cotton clothing becomes expensive. Cotton is not cultivated in Bangladesh itself, therefore it must be imported before it can be become part of clothing production. As the “Agreement on Textiles and Clothing” was phased out in 2005, many experts feared a possible collapse of the Bangladeshi textile industry because they now had to compete against China and India for orders. Bangladesh has managed to keep their contract partners from the EU and USA because production in Bangladesh is possible at an “extremely low wage level”.[3]

3) The discounter KiK and its methods

3.1 Profile of the garment discounter KiK

KiK was founded in 1994 by Stefan Heinig and the Tengelmann group. KiK is an abbreviation for the German slogan “der Kunde ist König”, which means “the customer is king”. The mission statement of KiK is that everyone can be fully dressed from top to tail for only 30 Euro. KiK is a quickly growing textile discounter. Today, KiK consists of 3,000 stores in Germany, Austria, the Czech Republic, Slovenia, Hungary and Slovakia. Each year about 200 new stores are opened. The annual turnover is more than 1 billion Euros. KiK is the largest textile discounter in Germany. The range of products includes on the one hand ladies, mens, children’s and baby wear, and on the other hand giftware, toys, accessories, home textiles, underwear and stockings. KiK uses the well-known German TV-starlet Verona Pooth for advertising their products as a testimonial. The company stresses that they offer good quality for a very cheap price. The quality is tested by the quality assurance management of KiK. In addition, KiK works together with the international testing institute SGS Fresenius and the TÜV institute Rheinland. On the KiK internet homepage customers can watch a short film that demonstrates the quality management.[5][6][7]

3.2 Market power of discounters

3.2.1 How discounter determine the prices

How can a discounter sell its products for such low prices? As you can read on the KiK homepage, their basic business model is to order a big number of items for each product and deliver them via an intelligent logistics system to their stores. It is important to plan an attractive product-range and be flexible enough to quickly order new products when they have sold-out.[6] The production of demanded clothes needs to be a “Just-in-Time” production, because this system allows a maximum of flexibility and very little costs for storage.[8]

The big volume orders have both advantages and disadvantages for the textile producers in Bangladesh. As an advantage, the factories are working to full capacity. This is a status that one should aspire to from an economic point of view. The workers have jobs and are paid. The problem is that such factories depend on only one huge client. If this client decides to search for a new producer, the whole factory is without an order. That means the machines stand idle and the workers are dismissed. The factory owner won’t have enough money to pay his bills such as rent or electricity costs. If he doesn’t get a new order he will soon go bankrupt. So, the dependence on one client is a clear disadvantage for the producers. The big client uses his power to keep the prices down. “The largest discounters pay their suppliers up to 15-20 percent less for their goods than normal department stores (ActionAid, 2007, p. 16)).”[3] The consequence of steadily decreasing prices is a reduction of the already low wages of the textile workers.

In Chapter 2 I mentioned the “Agreement on Textiles and Clothing” (ATC) of the World Trade Organisation that was phased out in 2005. After this phase-out greater competition between Bangladesh and the former restricted countries like China and India began with the consequence for Bangladesh – which is very dependent on exports of clothing – that price reductions started which were to be paid by the textile workers in the end. “The poor countries, competing to retain their clothing industry, try to offer the lowest wages.”[3]

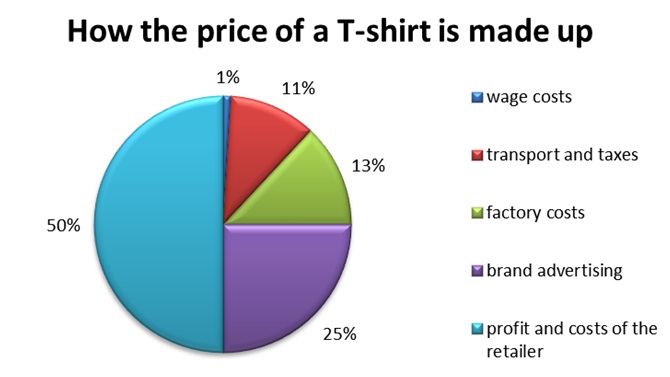

Figure 1 is adapted from the brochure of the “Clean Clothes Campaign”. It is necessary now to make a short presentation of the “Clean Clothes Campaign” because it offers important information in the brochure that is used as one of the key literature sources in this case study. The key aim of the “Clean Clothes Campaign” is to improve working conditions in the global textile industry, especially in less developed countries. This campaign is widely supported by many NGOs and labour unions.[9] The figure shows which price components a T-shirt price is made up of. “Wages account for only 0.5-1 percent of the ultimate selling price of the product”. A large share of the price is accumulated outside Bangladesh in Western industrial nations like Germany. Only the factory and wage costs remain in the Bangladeshi economy. A large amount of the final price is for marketing activities and the rest, about 50 percent is used to cover the costs of the retailer and to gain some profit.[3]

This figure 1 is adapted from the brochure of the “Clean Clothes Campaign”.[3]

To make it easier to understand, I would like to give a concrete example. If we think about 1% wage costs for a normal T-shirt that is sold to us for 20 Euro, only 20 cents from the price goes on wage costs. I think this is remarkable because it should be easy to increase wages without any massive price explosions. I even risk saying that none of the customers would recognize the effect of increased wages. The problem is that the discounters only think in large scales. If they want to lodge an order with a factory owner in Bangladesh they compare the complete price for their order. It is a highly competitive process in which only the quickest and cheapest supplier wins. How the factory owner manages to produce the required amount of clothing is not important for the discounter. This is the responsibility of the Bangladeshi factory owner. He also wants to make a profit and therefore reduces his costs, especially the wages of his workers. It is all a downward spiral to satisfy the dictated low prices of the huge discounters.

3.2.2 Three tendencies in purchasing practise

The big discounters who have huge market power use three main purchasing practises in their direct interaction with their suppliers from developing countries. These three tendencies are receiving their products “cheaper” and “quicker” and in addition include a reduction in their own risk by applying “risk-shifting” methods.

The prices are dictated by the big clients. The producer in Bangladesh accepts such low prices because otherwise he loses his order. Gisela Burkhardt, an expert in development politics, confirms that “suppliers are threatened with being removed from the lists if they do not reduce the price.”[3] Although the costs of energy have risen, the prices for textiles still decline. This is again only possible because the wage costs are reduced.

The second practise method is the pressure that is put on the suppliers in terms of time. The discounter demands quick production. There are two main causes for this demand. On the one hand, the fashion business today changes very quickly. Collections in the past changed only twice a year, but today there can be changes every month and that mean twelve times a year.[3] The discounter wants to be very flexible, which implies that their store-houses should act only like a logistic-centre where in-coming products are reorganised and immediately delivered to the final stores. So at best nothing stays long in the warehouses. This system is in fact very economic but needs a good workable, dependable and especially quick supply chain. Today the internet offers the possibilities of lodging an order for products that are produced on the other side of the world. Again, the producers are under pressure to react quicker than their competitors. They do not have enough time to calculate thoroughly. They depend on the orders and therefore no order is much worse than a bad order for a low price.

The last point is the risk-shifting procedure. It goes along with the need to be able to produce “just-in-time” when a powerful discounter lodges an order. The owner of a factory in Bangladesh needs to purchase the materials, like yarn, buttons, zips and cloth for the production at his own risk before he gets a new order. The delivery times have been shortened massively. An order received on Sunday has to be delivered by Wednesday.[3] “The company not only saves storage capacity, but also passes on all risks to the suppliers.”[3] The need to store materials for future production which hasn’t yet been ordered again increases the dependency of the Bangladeshi supplier on the big discounter.

3.3 “Code of Conduct” by KiK – What does KiK to guarantee labour standards?

Stefan Heinig, the CEO of KiK, points out: “At KiK, the social, ecological and economic added value is very important. This is why today we take advantage of our strength and size to campaign for the principles of sustainability and to promote continuous improvement. In 2006, we established a strict code of conduct to which all our suppliers are committed. We consequently work on the implementation of the entailed demands. Even though it needs a lot of effort, patience and the ability to take occasional setbacks, our measures in regards to social responsibility serve as role models in the discount domain and help to impose standards.”[10]

This statement is very important because KiK sets its own standards that it must achieve or otherwise can get criticised for. As a next step it is necessary to take a closer look at the code of conduct established by KiK in 2006. The code of conduct describes the social standards for all the trading partners of KiK, including those in Bangladesh and China. “The regulations of the code of conduct contain all the usual conventions of the International Labour Organisation (ILO) for good working conditions. These include adhering to maximum working hours and paying a minimum wage as well as a safe and clean working environment, freedom of assembly and collective bargaining and the prohibition of child labour.”[10]

3.3.1 "Control mechanism" during a social audit

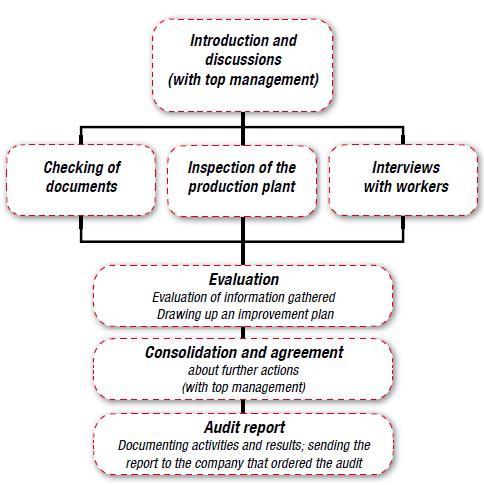

Adherence to the code of conduct rules is audited systematically by inspections that are carried out by independent audit organisations. These social audits follow a schedule that is shown in figure 2.

Figure 2: Schedule of a social audit at supplier factories in Bangladesh and China.[10]

The auditor arrives at the factory unannounced and starts his audit by talking to the management and asking for some documents. Then he inspects the whole factory with regard to working conditions, safety aspects and health requirements. He also chooses workers for a later interview. These interviews are carried out in the absence of the factory authorities.[10] “This means that they can find out whether the maximum working hours are adhered to and whether their monthly wages, including overtime, are paid correctly.”[10] After this, the auditor evaluates the factory and talks to the management about any inadequate standards and a suitable procedure to achieve the desired state. The audit report is send to KiK’s head office. After a while a re-audit takes place where all the criticised points are examined again.

I think the schedule describes a good audit and if it functions this way, it is definitely a good instrument to monitor adherence to the code of conduct. The next Chapter is based on a research study conducted in 2008 by the “Alternative Movement for Resources and Freedom” (AMRF), a Bangladeshi NGO at the request of the “Clean Clothes Campaign”. This study was made to reveal the real working conditions in the factories of the suppliers of KiK and Lidl. A team of researchers interviewed 136 workers in six factories. They answered questionnaires and 31 of them were asked in group discussions.[3] Chapter 4 will therefore present the opposite perspective to KiK’s claim. It shows how the rules and control-audits are circumvented and under what conditions the mostly female workers suffer.

4) Bangladeshi labour standards in supplier-factories of KiK

The research study from 2008 revealed that the labour standards at the Bangladeshi factories of KiK suppliers were very bad. The workers aren’t allowed to establish or join a labour union. The seamstresses have to regularly work overtime because they need to fulfil their daily quotas. These goals are set so high that it is impossible to fulfil them in regular working time. Work time is 9-14 hours a day, which makes 80-100 hours a week. To work overtime is not a voluntary option; everyone who says that he/she doesn’t want to do extra hours loses his/her work. They have to work 6 or 7 days a week. The majority of the workers are mostly young women who need their job to contribute to their family’s livelihood. They are really frightened of losing their job. They accept the bad working conditions because they can be replaced anytime by a new woman who is keen on this job. In the crowded city the work in the textile factories is the best job a young woman can get. When she loses it, she needs to return home to her poor village and suffer even more from hunger. The payment of the workers isn’t based on transparent criteria. The payment depends on subjective criteria like beauty, age or interaction with the male bosses. The date of payment is irregular, often too late (from the middle to the end of following month) and doesn’t match the working hours they actually performed. Overtime isn’t paid transparently either. The workers don’t have a labour contract and don’t get an overview of their working hours and the resulting payment. About 85% of factory workers are women. Women are paid worse than men. This is justified by saying that women do “lighter” work than men. Women who start to work in the factory again after a pregnancy lose their former payment status and must take a newcomer’s wage. The women suffer from discrimination caused by the bosses. Sometimes they are discriminated against, shouted at or even hit. In cases of illness, workers lose their jobs. There is no real health care system available. Health, hygiene and safety requirements are really bad. Drinking water is only available in one out of six factories. A factory canteen or day-care facilities for children are only in use when the auditor comes for a visit. Most of the workers have not even heard about a code of conduct. But they were forced to say that everything is alright in the factory when an inspection occurred. They were threatened with losing their jobs if they told the truth.[3]

Khorshed Alam is the leader of the Bangladeshi NGO “Alternative Movement for Resources and Freedom” (AMRF). He summarised the inspections in his report for the “Clean Clothes Campaign” that take place as follows: “During these visits, the factory owners put on a show. Toilets are cleaned. The workers are forced to declare that there is no child labour in their factory, that the working atmosphere is good and that their wages are paid on time. They should also say that they are entitled to take regular holidays, are not forced to work overtime and do not have to work at night. When questioned about their pay, they should say they earn more than they actually do. Workers who are very young or look too young are forced to stay away from work when buyers or auditors visit. In the case of unannounced visits, they are locked in the toilets. There are known cases of workers presenting the real situation to buyers and consequently being dismissed for doing so.”[3]

5) Summary and outlook

This case study focuses on the globalisation issue in a specific case. Globalisation leads to the opportunity to buy labour where ever you like for the cheapest price. Big discounters like the German clothing discounter KiK make use of the new opportunities and allow their clothing products to be produced in Bangladesh. The Bangladeshi economy benefits from this but also becomes dependent because about 76% of their export volume today is based on their textile industry. After the phase-out of the “Agreement on Textiles and Clothing” of the World Trade Organisation, price-reductions took place to keep client orders. The workers are at the lowest hierarchy level. They have to suffer directly from low prices and very short-term delivery promises.

The establishment of code of conduct systems like KiK’s is theoretically a very good idea. I think that such conduct would really help to improve working conditions in developing countries if they would be implemented in reality. The problem of the code of conduct is its voluntary form. The schedule for an unannounced audit sounds good, but it can be and really is undermined. The research study in 2008 by Khorshed Alam shows that voluntary codes of conduct aren’t useful. He was interviewed by the journalist Christoph Lütgert (“Panorama -- die Reporter” of the TV-channel ARD[11]) again in 2010 and he confirms his previous statement that little has changed since the code of conduct was put in place. Audits were made, but only at “good” factories or with well-prepared workers who were forced to say everything is really nice in the factory. Sometimes auditors even are tricked.

I do support the idea of establishing codes of conduct, but in my opinion it isn’t enough to delegate such inspections once or twice a year to an audit team that visits some factories only. I think a huge company like KiK should have a special and direct interest in social responsibility. They can actively do something for the workers at their supplier factories if they stress in their contracts that they are willing to pay a higher, “fair” price if the supplier is willing to pay higher wages to his workers and strictly follow the rules of the code of conduct. The payment and working conditions need to be controlled permanently by an alternating group of KiK management members who stay directly in the Bangladeshi factory. In such a monitoring system it is in fact impossible to present a “show” for one day. The daily monitoring would lead to a rise in a new feeling of security agmonh the workers. The problem of corruption is avoided by a steady rotation of auditors. In addition, the discounter should conclude a long-term contract with its supplier so that job security can be guaranteed.

It would be really good if such big discounters like KiK with their market power decide to follow my proposals, but I indeed take a very gloomy view of that. The consequence would be the establishment of governmental rules for worldwide trade and production. Governments or worldwide organisations like the WTO, the EU or the USA should agree on strict rules for labour conditions and create an independent powerful audit system. If the biggest industrial nations agree upon these rules of labour conditions they can link their imports to adherence to these rules. In this case, the developing countries and their clients would have a direct incentive to achieve the required aims because otherwise they could not export or import anything.

6) References

- ↑ UNFPA Weltbevölkerungsbericht 2010. Copyright © UNFPA 2010. http://www.weltbevoelkerung.de/pdf/dsw_datenreport_10.pdf

- ↑ Geographic information about Bangladesh. Retrieved February 25,2011 from http://travel.nationalgeographic.com/travel/countries/bangladesh-facts/

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 3.11 3.12 3.13 3.14 3.15 Burckhardt, G. (2008). Brochure of Clean Clothes Campaign: Who pays for our clothing from Lidl and KIK? Published at Kampagne für Saubere-Kleidung (Clean Clothes Campaign; CCC). Available from http://www.saubere-kleidung.de/downloads/publikationen/2008-01_Brosch-Lidl-KiK_en.pdf

- ↑ Backhaus, N. (2009). Globalisierung. Published by Prof. Dr. Rainer Duttmann, Prof. Dr. Rainer Glawion, Prof. Herbert Popp, Prof. Dr. Rita Schneider-Sliwa. Braunschweig: Westermann Bildungshaus Schulbuchverlage, 171.

- ↑ Data and facts about KiK. Retrieved February 26, 2011, from http://www.kik-textilien.com/fileadmin/Abteilungen/Kommunikation/Presse/Zahlen-Daten-Fakten-KiK_2011.pdf

- ↑ 6.0 6.1 KiK - company profile. Retreived February 26, 2011 from http://www.kik-textilien.com/unternehmen/presse/pressearchiv/unternehmensprofil/pm-unternehmesportait/

- ↑ KiK company film. Retrieved February 26, 2011 from http://www.kik-textilien.com/unternehmen/presse/pressearchiv/unternehmensfilm/

- ↑ Backhaus, N. (2009). Globalisierung. Published by Prof. Dr. Rainer Duttmann, Prof. Dr. Rainer Glawion, Prof. Herbert Popp, Prof. Dr. Rita Schneider-Sliwa. Braunschweig: Westermann Bildungshaus Schulbuchverlage, 167.

- ↑ Profile of Clean Clothes Campaign. Retrieved February 28, 2011 from http://www.saubere-kleidung.de/ccc-60_wir/ccc-60_wir-ueberblick.html

- ↑ 10.0 10.1 10.2 10.3 10.4 CSR brochure of KIK. (2010, October). Retrieved February 26, 2011 from http://www.kik-textilien.com/uploads/media/CSR-Broschuere_eng.pdf

- ↑ ARD-exklusiv: Die KiK-Story. (2010, August 4). Available from http://www.ardmediathek.de/ard/servlet/content/3517136?documentId=5063630

--Reibe 17:50, 28 February 2011 (CET)

Corrected version after peer review: --Reibe 15:45, 7 March 2011 (CET)

Preliminary writing stage - literature review (Caroline Reibe)

| Author: Caroline Reibe. This article was published under Creative Commons Attribution-Share Alike 3.0 Unported License. How to cite the article: Caroline Reibe . (11. 09. 2025). “The Low Price” of the textile discounter KiK – consequences for labour conditions in textile factories in Bangladesh. VCSEWiki. Retrieved 01:36 11. 09. 2025) from: <https://vcsewiki.czp.cuni.cz/w/index.php?title=%E2%80%9CThe_Low_Price%E2%80%9D_of_the_textile_discounter_KiK_%E2%80%93_consequences_for_labour_conditions_in_textile_factories_in_Bangladesh&oldid=1910>. |